Our Vision and Goals

The reduction in CO2 emission is a globally recognized challenge and will require transitioning from fossil-based to bio-based products for a sustainable society.

Our vision is to position lignin as one of the leading bio-based candidates through breakthrough-enabling technologies that produce user-customized lignin of high quality.

We strive for circularity, process- and product-integration, complete chemical- and material recovery, and CO2 emission-free process.

We aim to support reseachers, as well as the biochemical- and biomaterial industries with bio-based precursors of high quality for customized products.

FPP Process

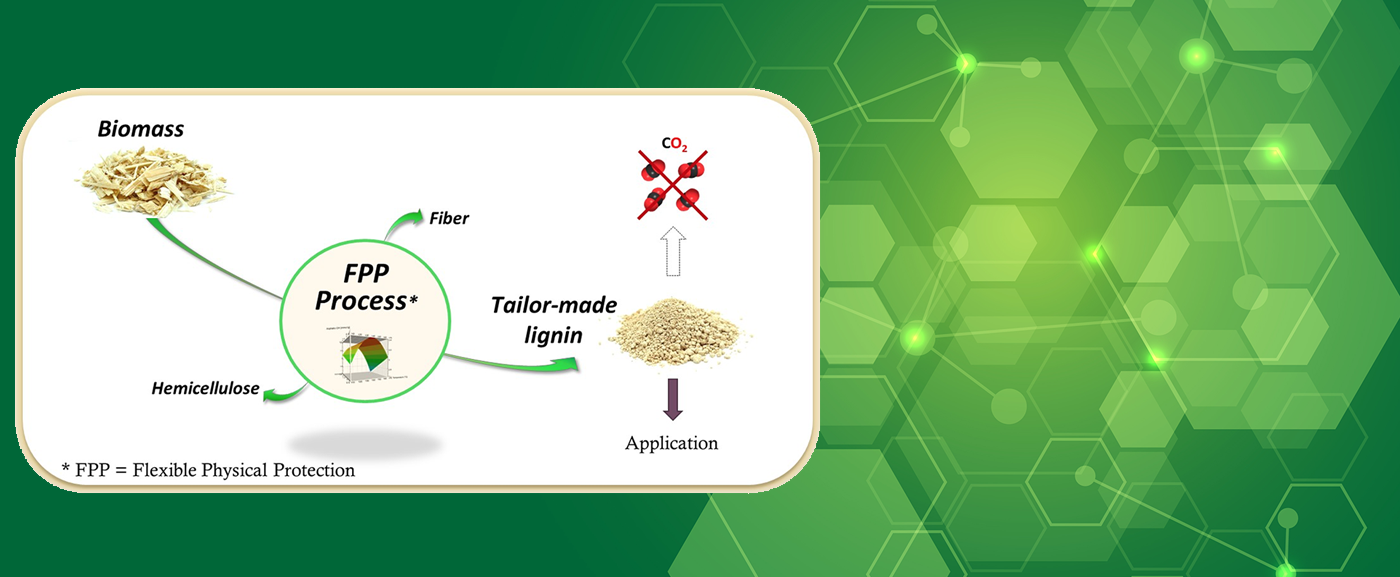

The flexible physical protection (FPP) process is based on a patent-pending technology and facilitates the production of lignin with tailored chemical and physical properties.

The raw materials primarily include currently underutilized waste material from the forest industry such as sawdust, bark, and agricultural waste, but can also include traditional wood chips.

The process is integrated, producing hemicelluloses and fibers as secondary products.

The core innovation in the technology adopts the principle of physical protection, tweaked with reaction parameters that can be used to selectively tailor molecular properties for customized applications.

Proligreen Lignin and Applications

Features: Proligreen lignins have high purity levels, are bright colored and are odorless. The molecular structures are well-characterized.

Applications: Proligreen lignins have good potential for several applications, e.g. production of biochemicals, biofuels and as buiding blocks for bio-based materials.

About Us

Proligreen AB is a spin-off company from KTH, Royal Institute of Technology.

News

Our Research and Related Publications

The Flexible Physical Protection (FPP) process and technology are based on research performed at the Wallenberg Wood Science Center (WWSC) at KTH, Royal Institute of Technology. In a nutshell, fundamental knowledge of plant cell walls, lignin structure, and reactivity are combined with mild extraction protocols adopting physical protection strategies that can be fine-tuned to produce lignin with tailored properties for customized applications. Details on the fundamental work can be found in the references below.

iScience, 2023, 26 (9), 107507. 10.1016/j.isci.2023.107507

Green Chemistry, 2022, 24 (6), 1211-1223. 10.1039/D1GC04171A

ChemSusChem 2020, 13 (17), 4666-4677. 10.1002/cssc.202000974

Contact

Are you interested in testing Proligreen lignin for your application? Feel free to contact us.

maria@proligreen.com